Alu Clad Windows The Lumis alu-clad window is a modern and stylish flush casement system that combines a glued scantling core with aluminum cladding. This innovative construction, combined with adjustable fittings, allows Lumis windows to achieve exceptional aesthetic features, high levels of airtightness, and meet the burglary protection requirements set by the PAS24 standard. Whether you're looking for windows for a new construction project or to upgrade your current windows, Lumis offers an ideal solution that combines functionality with aesthetics.

Tested heat transfer coefficient (window U value): Uw = 0.76 W/m2K

Single frame, frame dimension 56×92 mm, sash dimension 56 x 61 mm. All technically possible shapes and dimensions.

Engineered wood – selected or fingerjointed Pine, meranti or oak timber.

Sound reduction for the standard unit Rw = 31 dB. Glazing unit with improved sound absorption (option) for Rw = 34-42 dB, depending on a selected glazing unit.

Double-glazing, single-chamber (4-18Ar-4), 26 mm unit, the heat transfer coefficient Ug = 1.0 W / m2C (BS EN-674), inter-pane cavity filled with argon.

Triple-glazing, twin-chamber (4-18Ar-4-18Ar-4), 48mm unit, the heat transfer coefficient Ug = 0.5 W / m2K (EN-PN 674), inter-pane cavity filled with argon. Ornamental glass, safe, with sun protection properties – option. Ornamental glass, safe, with sun protection properties – option. The maximum thickness of the triple glazed unit is 54mm. Warm edge spacer (grey) – standard.

Vienna (glued wooden + internal aluminum widths: 22, 32, 42mm), inter-pane, constructionwidths: 60mm or 80mm.

Supplied by IPA Denmark.

Side hung, Side swing 90°, Fully reversible horizontal, Top hinge, Top slide, Reversible vertical

Transparent paints according to Sigma Coatings colour chart. Opaque paints according to RAL and NCS colour charts. 4 coating system, impregnation, primer, interlayer, topcoat.

Single gasket Q-LON 3053 supplied by Schlegel. Glass gaskets: both sides black 3 mm gasket supplied by Deventer.

Aluminum cladding cut 45° Mechanically gripped or welded. Colors according to RAL color cart. Cladding supplier Aluron.

Silikon Wacker lub Perennator, colours: transparent, white, light brown, dark brown, black

Uni Windows Ltd. offers a 10-year warranty on labour and materials used.

One chamber heat insulating glazing unit comprises of two glass panes, including one Thermofloat glass pane with invisible layer of inert metals combination (so-called “low emission layer”). Two chamber heat insulating glazing units comprise two Thermofloat glass panes.

The space between glass panes is filled with Argon or Krypton gas, which further reduces heat transfer coefficient Ug. Protection against gas leak at the glass pane perimeter is ensured by warm distance frame with two-step sealing of plastic.

Insulated glass (double, triple or quadruple glazing) filled with Argon as standard is glass with the lowest coefficient of heat transfer. The insulating quality is achieved by applying a thin layer of metal on the inside of the inner glass that reflects heat back into the room and at the same time allows heat from solar radiation to penetrate. Ordinary double glazed unit has a heat transfer coefficient Ug = 2.8 W/m2K. In our windows, as standard we use glass with a heat transfer coefficient Ug = 1.0 W/m2, this value can be reduced by up to Ug = 0.5 W/m2 using a special triple glazing or Ug = 0.3 W/m2 for quadruple glazing.

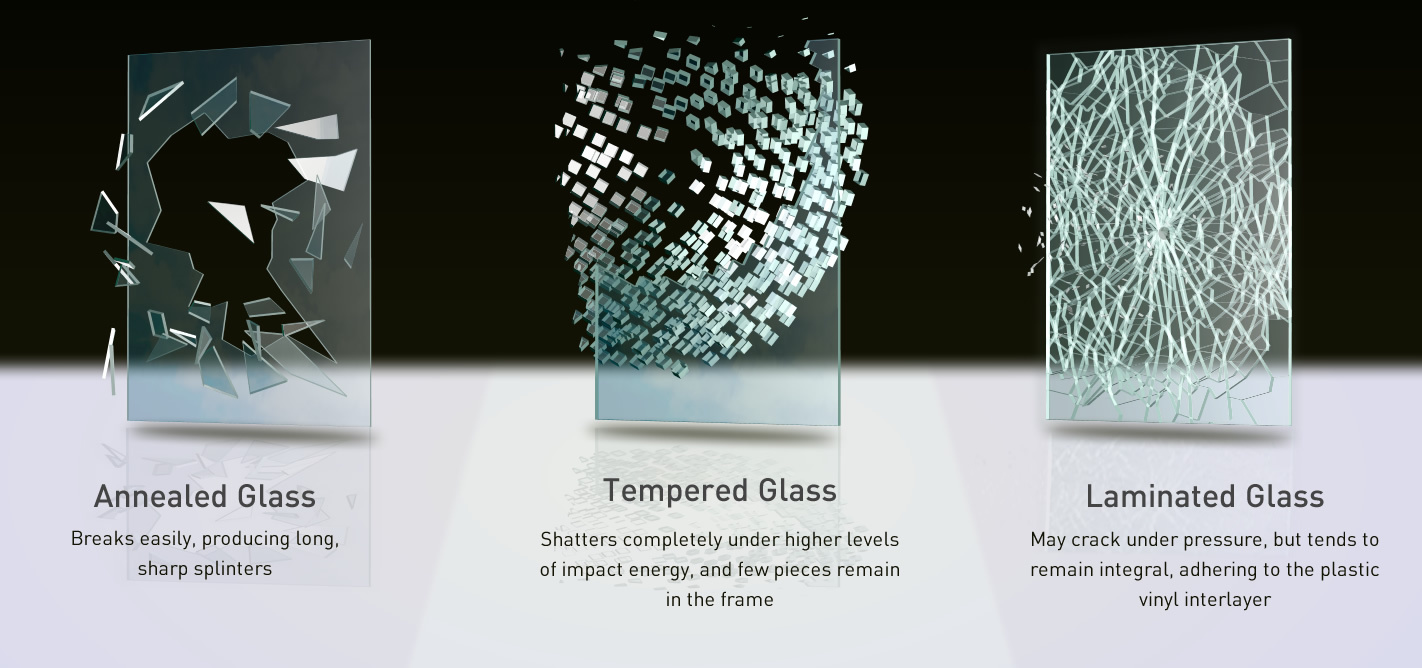

Laminated glass is most known for being used on the windscreens of the majority of the world’s cars. This global use can be put down to what happens when laminated glass shatters.

When smashed, laminated glass holds in place and does not break up into large jagged shards or hundreds of little pieces. Instead, it keeps in place long enough for a replacement to be found.

This happens thanks to the plastic (polyvinyl butyral) interlay that is sandwiched between two glass sheets during manufacture. This bonds the two panes together like a glue so that even when the glass breaks, its fragments keep binding on the thin film.

This highly practical safety feature greatly reduces the chances of injury occurring from falling glass.

In addition to this, as the panes do not burst apart on impact, laminated glass leaves no hole behind for intruders and thieves to crawl through. Laminated glass also offers far superior UV resistance and sound proofing to annealed glass.

There are several different types of laminated safety glass built to withstand a specified level of attack. These include for blast-resistance glass, fire-resistance glass, bullet-resistance glass and solar control laminated glass.

Toughened glass, also known as tempered glass after its method of production, is a type of safety glass that is five times stronger than annealed and laminated glass of the same size and thickness.

Toughened glass gets this strength from the tempering process which sees it subjected to intense heating followed by rapid cooling during manufacture.

This toughness gives tempered glass a far higher load and breakage resistance. Toughened glass needs to be hit a lot harder than other safety glass in order to break.

Whereas laminated glass holds in place when shattered, toughened glass breaks up into hundreds of tiny pieces. You will probably have seen this on the floor where a telephone box or bus stop had been vandalised.

This method of breaking lowers the risk of injury compared to annealed glass which breaks up into larger, jagged pieces more likely to injure anybody in close proximity.

Tempered glass has a heat resistance four to five times stronger than standard glass and can withstand high temperature changes up to 250°C.

Aesthetic, functional values and protection of privacy

The increased use of glass as a modern decorative material leads to the necessity of satisfying the specific requirements which designers and architects place before it. Thus, ornamental glass should let the light come inside a room enhancing the warmth and depth of its features while at the same time preserving its privacy. The ornamental glass offered by UNI WINDOWS boasts the highest quality and a unique style to match. By changing the structure of the glass, we can change the degree of its transparency.

Protection against noise is one of the most important issues in our lives. The condition of assuring appropriate comfort and sometimes living in a given place is the assurance of a low level of noise.

Our subjective perception of noise is subject to the following principle: if the level of noise in a room is reduced by 10 decibels in relation to that outside, we get the impression that it is reduced by half. Noise protection must be applied everywhere where noise cannot be completely eliminated. In such applications we are faced with acoustic double and triple glazed units.

Acoustic double and triple glazed units construction is based on the asymmetry of the assembled panes of glass, flexible bondsing of the panes, and the use of attenuation gases in the space between the panes. Acoustic double and triple glazed units can achieve the acoustic insulation factor Rw = 31 – 45 dB, depending on the type of unit.

Solar control glass can be divided into absorptive and reflective glass, based on their visual characteristics and the ability to reduce solar radiation. UNI WINDOWS offers three types of solar control glass:

– THE SELECTIVE float glass – flat and transparent, neutral or dyed to blue, brown, grey or green in the glass structure, and coated with a metal oxide multilayer, with the aim of achieving the appropriate effect of reflection, control of isolation of rooms, as well as limiting the penetration of solar energy plus a high level of thermal protection. It may be used only in double glazing.

– THE ABSORPTIVE float glass, flat and transparent, with blue, brown, grey or green tint. It may be used in single glazing or double glazing. This is applied to reduce the transmittance of solar energy.

– TTHE REFLEXIVE float glass – flat and transparent, neutral or dyed to blue, brown, grey or green in the glass structure, while also coated with metal oxides for proper reflective effect. This is applied to control light, and reduce solar energy transmittance. It may be used in single glazing or double glazing – regarding a type of coating.

Aluminium has significantly greater heat conductivity than the remaining window components. The aluminium spacer bar around the edge of the glass pane is the last route of excessive heat penetration from the room to the exterior. This effect has been taken into account in the new approach to calculation of the coefficient Uw of the window and has been described with coefficient Psi (Ψ). The solution to this problem may be the application of a spacer bar – called warm edge*, executed from compound insulation material or fine steel.

To the time of establishing clear criteria enabling the definition of the warm edge concept, many spacer bars in glass units were sold on the market, which were indeed warmer than aluminium bars however had incomparably worse properties than correct solutions. According to this bars with improved design standard parameters are those, in which the spacer bar fulfils the following inequality:

Σ (diλi) ≤ 0,007 W/K

where:

di – thickness of partition material

λi – conductive projection of material in W/mK

Example: 2(d1λ1) + (d2λ2) ≤ 0,007 W/K